The production of our core products—gelatin and collagen peptides—requires significant amounts of energy and water. While promoting recycling, we are working to use energy more efficiently and to reduce CO₂ emissions and the use of water resources.

In addition, dicalcium phosphate (DCP), a by-product of bovine bone gelatin, has been found—through joint research in recent years with the National Institute of Technology, Toyama College—to fix fluorine contained in water and soil, preventing excess fluorine from leaching into the environment.

By leveraging our unique technologies, we aim to contribute to society by offering new methods of environmental improvement.

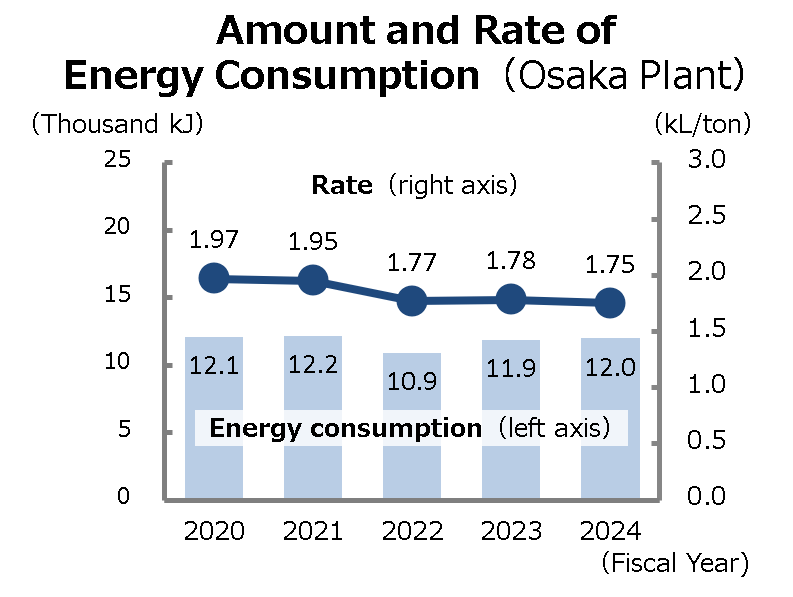

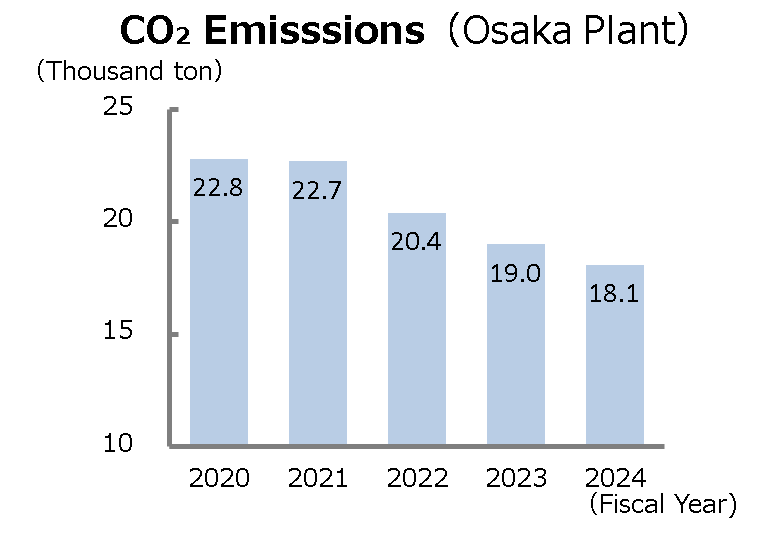

At our Osaka Plant, we are working to improve energy efficiency and enhance production processes by upgrading equipment such as hot and chilled water units, boilers, and the cogeneration system. Operation divisions are also promoting energy saving by managing room temperatures and turning off office equipment when not in use.

In fiscal 2023, we focused on improving energy efficiency and optimizing facility operations. As a result, we reduced energy consumption per unit of production by 1.3% and CO₂ emissions by 4.3% compared to the previous fiscal year.

As part of our commitment to environmentally responsible business activities, we disclose environmental information in line with the recommendations of the Task Force on Climate-related Financial Disclosures (TCFD), ensuring proper monitoring and transparency of our environmental data.

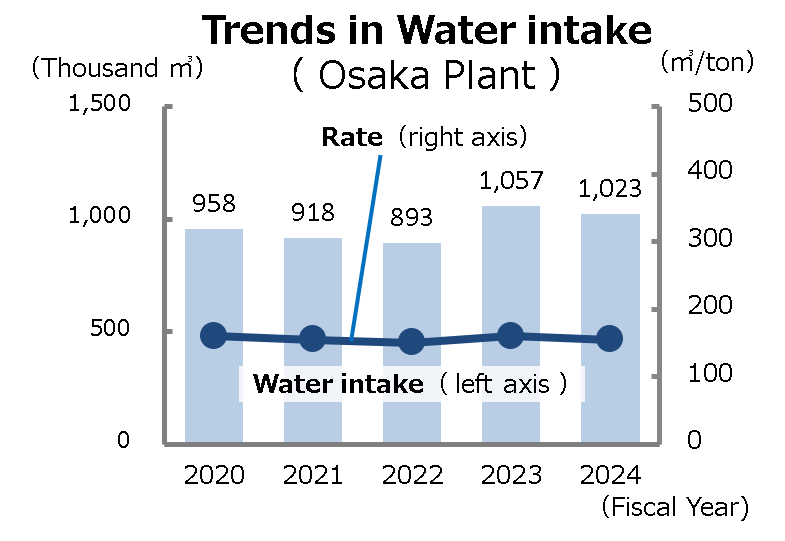

Large amounts of water are used in the gelatin manufacturing process. In addition, to maintain and improve quality, a significant amount of water is needed for cleaning equipment. In fiscal 2023, we achieved a 5.4% year-on-year reduction in water intake per unit of production. This was the result of efforts to reduce water intake and reuse water while maintaining product quality.

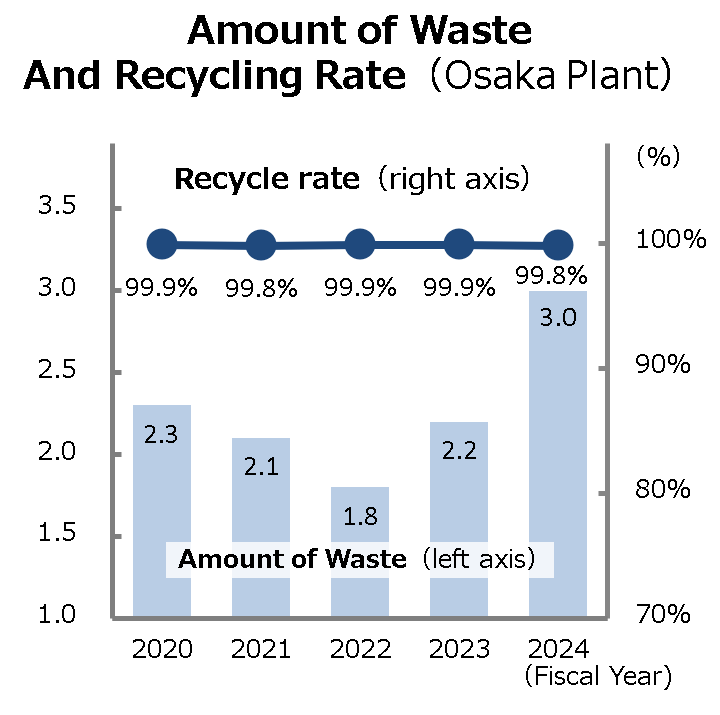

In fiscal 2023, a portion of the sludge from our wastewater treatment process that had previously been used as fertilizer was reclassified as waste, resulting in an increase in total waste volume. To address this, we modified our facilities in fiscal 2024 to reduce the added waste, with a projected decrease starting in fiscal 2025.

Our overall waste recycling rate—including thermal recycling—remains high at 99.8%, maintaining a near-complete recycling level.

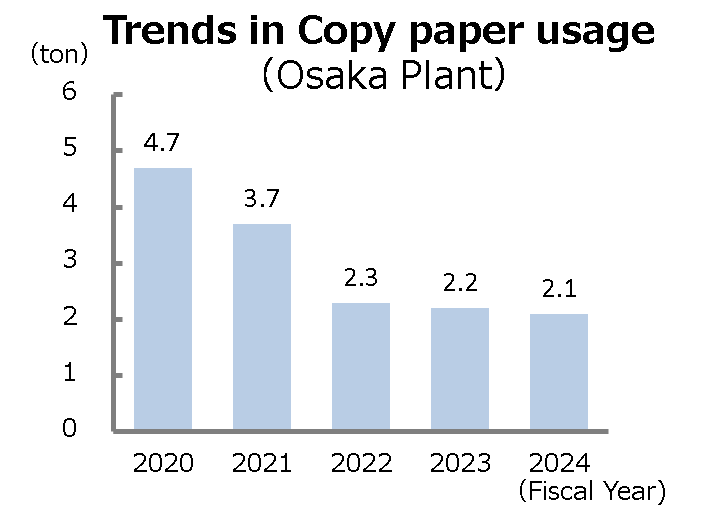

Since fiscal 2020, we have actively promoted paperless operations across all departments. As a result, copier paper usage in fiscal 2023 was reduced to less than half of the fiscal 2019 level.

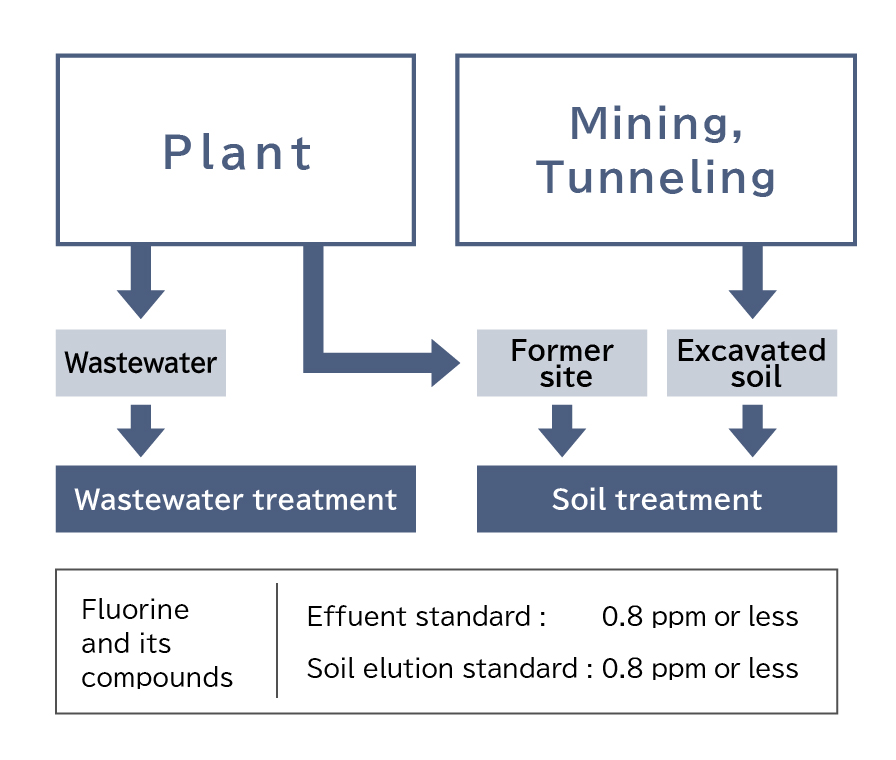

DCP is a by-product of processing bovine bones into gelatin raw materials.

Our DCPs have been found to efficiently insolubilize and stabilize fluorine. This makes it effective as a fluorine fixative in soil and wastewater (joint research with the National Institute of Technology, Toyama College).

When our DCPs are used for treating wastewater and soil, fluorine, a common soil and water pollutant, can be efficiently insolubilized and stabilized, and then removed.