We are working to reduce our CO_{2} emissions and water consumption, as well as working to recycle more waste and reduce landfill. In addition, it was found that dicalcium phosphate (DCP) generated when processed into bovine bone gelatin raw material can efficiently insolubilize and stabilize fluorine. This makes it effective as a fluorine fixative in soil and wastewater.

The EMS at the Osaka Plant has set targets to reduce the impact of production activities on the environment thereby working to reduce its impact on the environment.

To help realize a society capable of sustainable development, we will continue to carry out business activities in consideration of society, local communities, and all the people who work in the Nitta Gelatin Group.

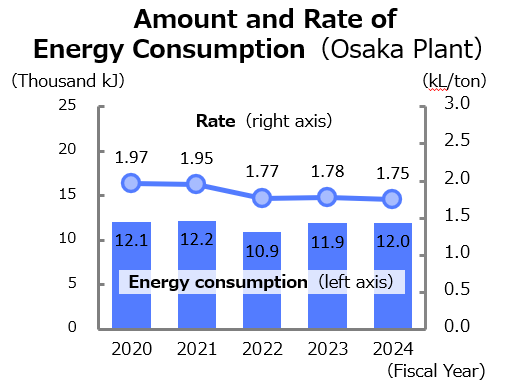

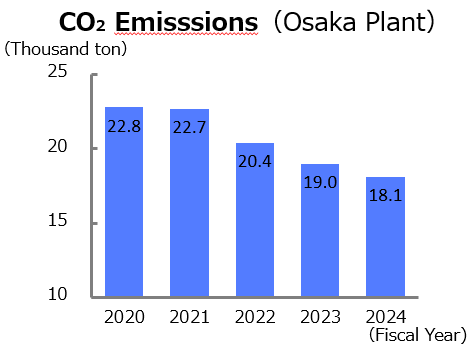

At the Osaka Plant, we are working to enhance energy efficiency and improve our manufacturing processes by upgrading heating and cooling machines, boilers and cogeneration systems. Operation divisions are also helping to save energy by managing room temperatures and turning office equipment off when not in use.

In fiscal 2024, as a result of efforts to improve energy efficiency and equipment operation, we were able to reduce production energy usage by 1.3% from fiscal 2023. We also achieved a 4.3% reduction in CO_{2} emissions from fiscal 2023.

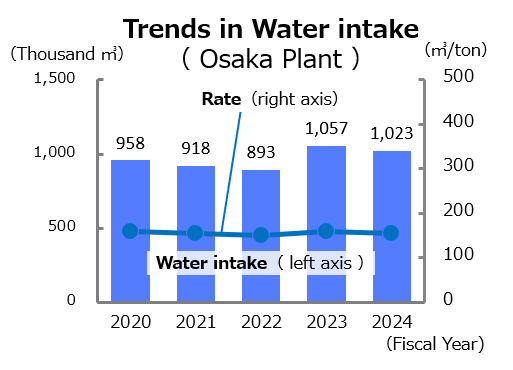

Large amounts of water are used in the gelatin manufacturing process. And in order to maintain and improve quality, a lot of water is needed for cleaning equipment.

In fiscal 2024, we achieved a 5.4% reduction in water intake per unit from fiscal 2023. We made efforts to reduce water intake and reuse while maintaining product quality.

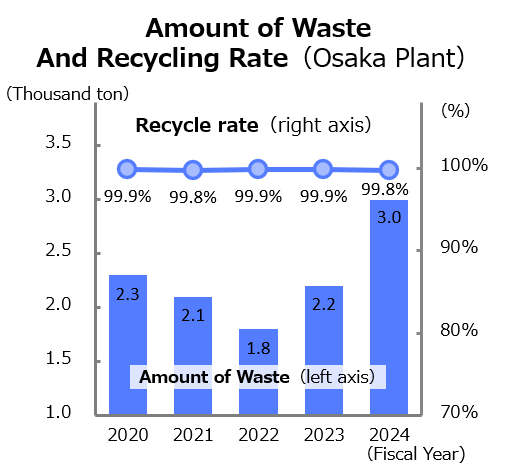

The amount of waste is increasing because some of the sludge from the wastewater treatment process, which had been converted to fertilizer, was changed to waste in fiscal 2023. However we are implementing equipment modifications in fiscal 2025 to reduce waste.The amount of waste is scheduled to decrease from fiscal 2026 onwards.

The recycling rate (including heat recycling) of all waste is currently at 99.8%, meaning we have been able to maintain a level very close to 100%.

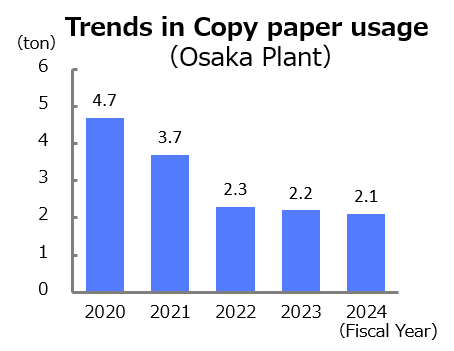

We have actively promoted paperless operations in all departments since fiscal 2021. As a result, the amount of copy paper used in fiscal 2024 has been reduced by more than half compared to fiscal 2020.

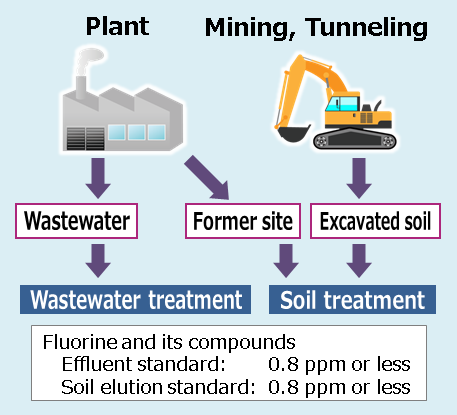

Dicalcium Phosphate (DCP) is a by-product of processing bovine bones into gelatin raw materials.

Our DCPs have been found to efficiently insolubilize and stabilize fluorine. This makes it effective as a fluorine fixative in soil and wastewater. (Joint research with the National Institute of Technology, Toyama College.)

When our DCPs are used for treating wastewater and soil, fluorine, a common soil and water pollutant, can be efficiently insolubilized and stabilized, and then removed.