The production of our core products—gelatin and collagen peptides—requires significant amounts of energy and water. While promoting recycling, we are working to use energy more efficiently and to reduce CO₂ emissions and the use of water resources.

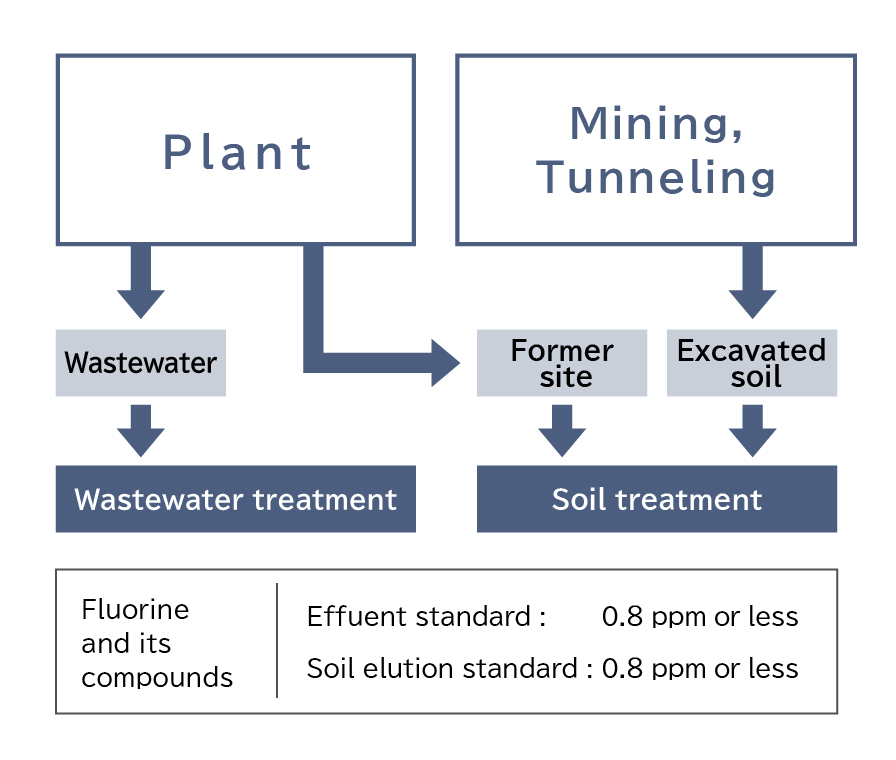

In addition, dicalcium phosphate (DCP), a by-product of bovine bone gelatin, has been found—through joint research in recent years with the National Institute of Technology, Toyama College—to fix fluorine contained in water and soil, preventing excess fluorine from leaching into the environment.

By leveraging our unique technologies, we aim to contribute to society by offering new methods of environmental improvement.

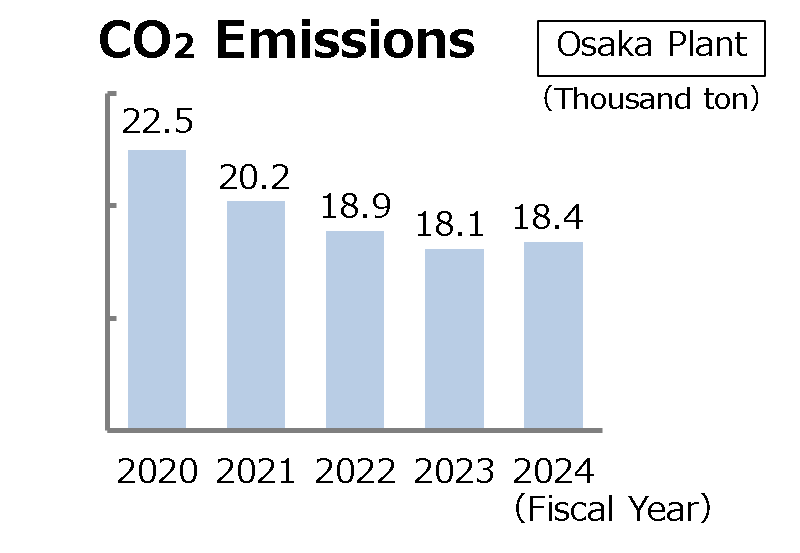

In fiscal year 2024, CO₂ emissions for the entire Osaka Plant increased by 2.1% year-on-year, failing to meet our targets. This was primarily due to an increase in operating days for some drying equipment in the first half of the year, aimed at ensuring stable operation of the wastewater treatment facility. Additionally, high-load operation of cooling equipment for gelatin production, driven by rising summer temperatures, contributed to the increase.

We aim for further CO₂ emission reductions in fiscal year 2025, thanks to the wastewater treatment process load reduction equipment that began trial operation in FY2024.

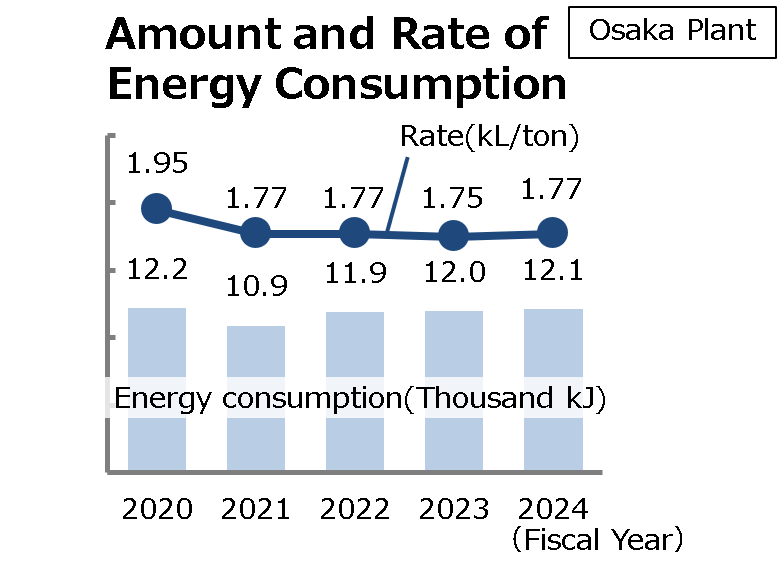

In fiscal year 2024, our manufacturing energy intensity increased by 3.4% year-on-year, falling short of our targets. This was influenced by similar factors that led to the increase in CO₂ emissions. We're committed to promoting energy conservation through optimizing the operation of energy-consuming equipment and considering upgrades to high-efficiency equipment.

For fiscal year 2025, we plan to optimize the operation of the aeration device in the wastewater treatment process to further reduce energy intensity.

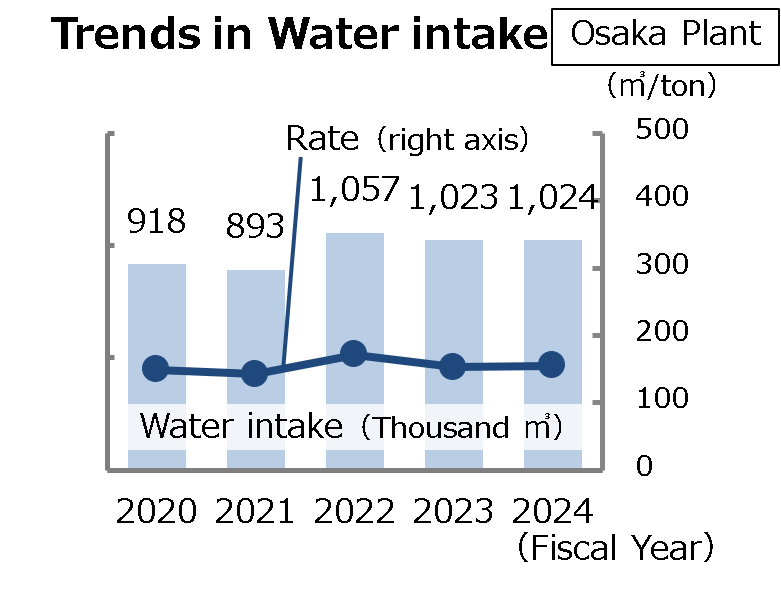

Large amounts of water are used in the gelatin manufacturing process. In addition, to maintain and improve quality, a significant amount of water is needed for cleaning equipment. In fiscal year 2024, our water intake intensity slightly increased from the previous year's results, causing us to miss our target. We will continue to strengthen our efforts to reduce water intake and promote water recycling, all while maintaining product quality.

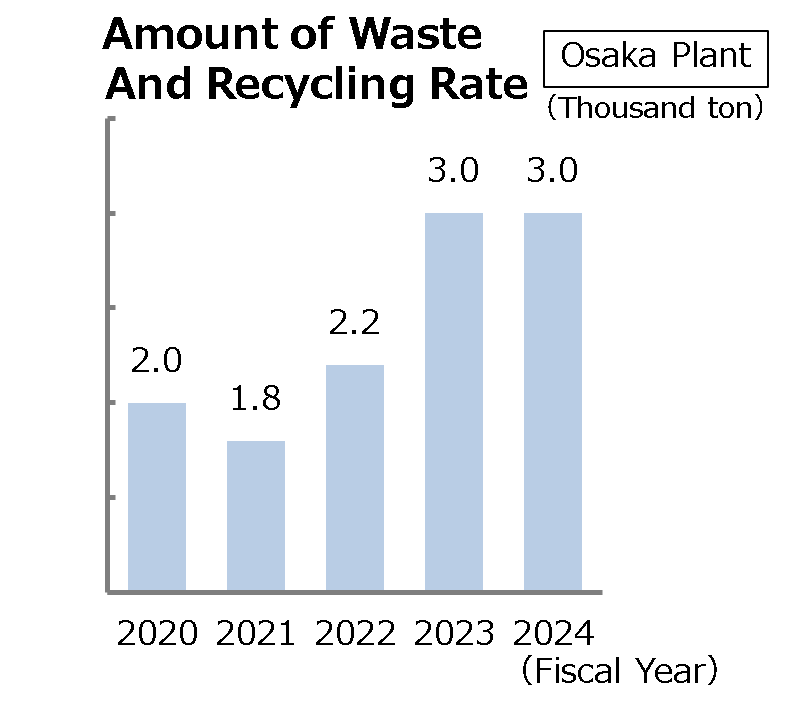

In fiscal year 2023, we reclassified a portion of the sludge from our wastewater treatment process, which had previously been used as fertilizer, as waste. This change led to an increase in our total waste volume. To address this, we modified our facilities in fiscal year 2024 and began trial operations aimed at reducing this increased waste. We expect stable operation of this equipment to lead to a reduction in waste volume from fiscal year 2025 onwards.

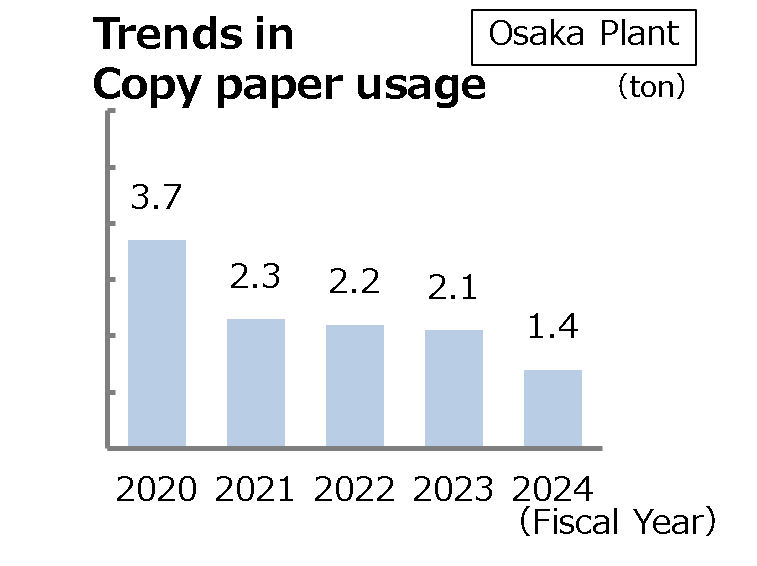

Since fiscal 2020, we have actively promoted paperless operations across all departments. As a result, our copy paper consumption in fiscal year 2024 was 1,378 kg, a significant reduction from the previous year's 2,100 kg, allowing us to achieve our goal. This represents approximately a 70% reduction compared to fiscal year 2019. We'll continue our efforts to reduce paper consumption through the digitalization of business processes and other initiatives.

DCP is a by-product of processing bovine bones into gelatin raw materials.

Our DCPs have been found to efficiently insolubilize and stabilize fluorine. This makes it effective as a fluorine fixative in soil and wastewater (joint research with the National Institute of Technology, Toyama College).

When our DCPs are used for treating wastewater and soil, fluorine, a common soil and water pollutant, can be efficiently insolubilized and stabilized, and then removed.